What is CNC Precision Manufacturing?

One of the biggest challenges many people run into when looking for the support of a professional precision machining shop is understanding what exactly this type of service can provide to them. At H & H Precision, Inc. in Haslet, TX, our team of skilled precision machinists, engineers, and fabrication specialists understand how confusing it can be to have a clear idea of precision machining if you’ve never been exposed to the work before. To help our readers, and our clients get a better understanding of the types of services we can offer, we decided it would be helpful to spend some time going over the broad strokes of the topic.

The Basics of Precision Machining

In simple terms, precision machining is a process that has been used to create a wide variety of objects that many of us use in our daily lives. Every part that is incorporated into many of these items requires the skills and design experience of a shop like ours. Also, damaged tools or worn machines often require recalibration, welding, or other specialized maintenance services that should be handled by precision machinists. From manufacturing aircraft aluminum alloys to surgical bone piercing equipment and customer-specific automotive tools, precision machining has a presence in all technologies and industries. In other words, if an object contains parts, it probably required precision machining.

The Equipment Behind the Process

Quality precision machining requires the ability to follow very specific drawings made with CAD (computer-aided) or CAM (computer-assisted) programs such as AutoCAD and TurboCAD. This type of advanced software can help create complex three-dimensional diagrams or contours that are needed to make instruments, machines, or objects using state-of-the-art hardware. These images must be followed in detail to ensure that the final product maintains the right quality and integrity. While most precision machinery companies work with some sort of CAD / CAM program, they often work with hand-drawn sketches in the early stages of design.

What Materials are Involved?

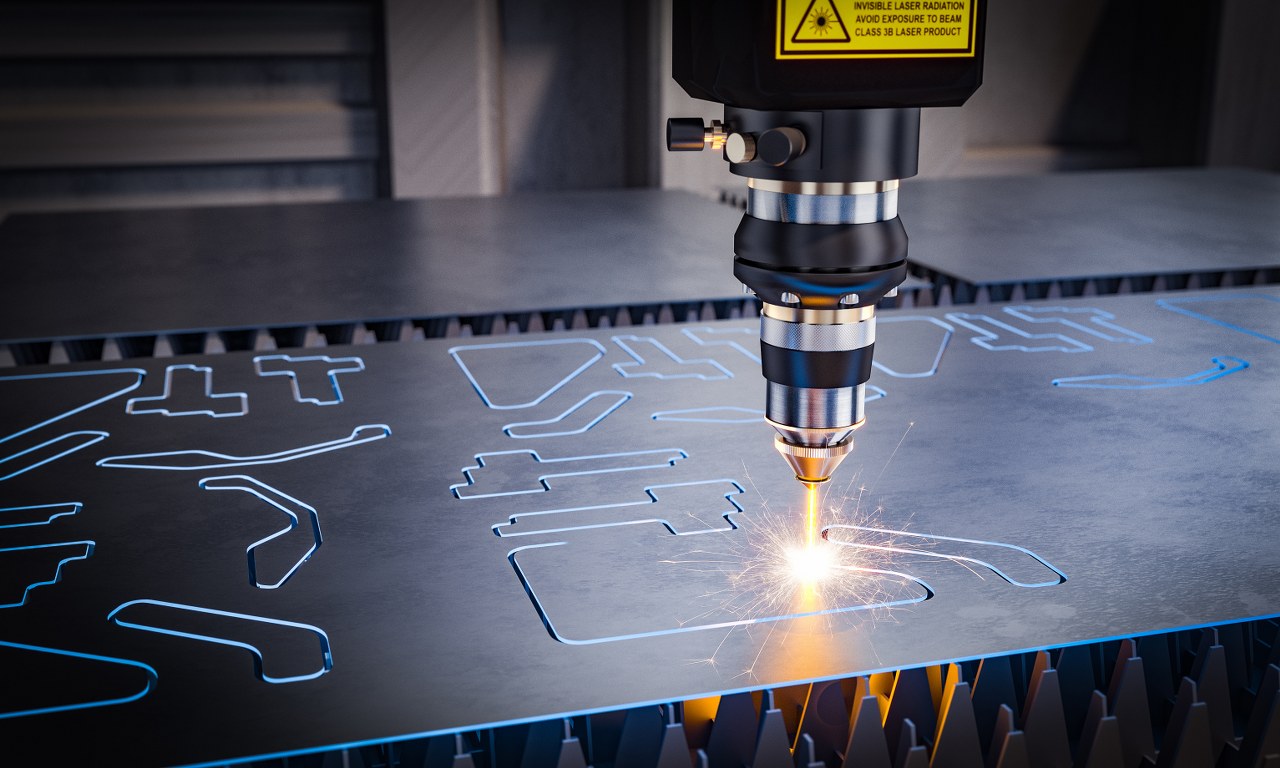

Precision machining can be utilized for projects involving many materials, including steel, bronze, graphite, glass, plastic and more. Depending on the size of the project and the material to be used, various precision machining tools are used. Any combination of lathes, mills, drilling machines, saws and grinders, and even high-speed robots can be used. The aerospace industry can use high-speed processing, while the woodworking industry can use photochemical etching and more specific milling processes. Production can involve anything from a single prototype of certain items to thousands of mass-produced products. Proper processing often requires CNC device programming, which means that they are controlled by a computer. With a CNC device, the right dimensions can be maintained throughout the production cycle.

So, What is CNC Machining?

Computer Numerical Control (CNC) is a term that is used to define the automation of machine tools using a computer that executes a programmed sequence of control commands. This is different from machines that are operated manually using handwheels or levers or which are only automatically driven by a cam.

With today’s technology and innovation, CNC systems allow for increased automation of the processes related to the design of mechanical parts and their production. The mechanical dimensions of a part are defined by computer-aided software (CAD) and then translated into production instructions with computer-aided software (CAM). The resulting instructions are converted to the specific instructions needed by the machine to make components and then loaded into the CNC machine.

The Power of Programming

When it comes to the process of CNC involved precision machining, machines are operated via highly specialized control systems. As part of this process, a software program is designated to control a specific tool. The computer language behind CNC machining is sometimes referred to as G-code, and it’s written to control the various behaviors of a corresponding machine, including the speed of movement, rate of feeding, and even precise coordination elements.

In general, CNC machining allows software applications to pre-program and position machine tool functions in predictable repeatable cycles without involving human operators. Thanks to the precise nature of this type of control system, there is plenty of unique possibilities for projects. The process is accepted in all areas of the manufacturing industry and is very important, especially in the fields of metal and plastic production.

Ask H & H Precision, Inc. in Haslet, Texas for More

If you’re looking for a precision machining shop in the Dallas / Fort Worth, TX area to bring your next business idea or project to life, you don’t need to search any further. Our team of experienced precision machining specialists and engineers has been working with clients throughout the DFW Metroplex for more than 30 years, and we’re always ready to consult with you on a project or design you want to take from concept to reality. Don’t hesitate to contact us today to learn more about our services or to schedule a consultation!